Running a generator on a low load can cause several problems such as internal glazing and carbon build up. This common problem in generator sets is a result of failing to follow application and operating guidelines. The typical recommendation for running diesel generators is at around 60-75% of their maximum rated load. The endothermic engines that are used in generator sets are designed to use as much power as possible from about 30-100% of the supposed maximum power.

The actual engine load will depend on the power that the installation demands. Short periods of low load running are permitted only if the set is brought to or close to full load on a regular basis. Although several problems can arise, here are 3 dangers we’ve highlighted of running a generator on a low load:

1. Poor Combustion

Poor combustion leads to soot formation and un-burnt fuel residues which clogs and gums piston rings (a split ring that fits into a groove on the outer diameter of a piston in a reciprocating engine, in this case the generator). This forms hard carbon that causes injectors to become clogged with soot, causing more deterioration in combustion and black smoking. Acids form in the engine oil caused by condensed water and combustion by-products which usually boil off at higher temperatures only complicate the problem further. Unsurprisingly, this causes slow but extremely detrimental wear to the bearing surface.

Normal maximum oil consumption on engines is around half of a percentage of the full load fuel consumption. All diesel engines must be run above 40% loading to allow for complete fuel combustion, and operation of engine at the correct cylinder temperatures. This rings true especially for the first 50 hours of operation of the engine.

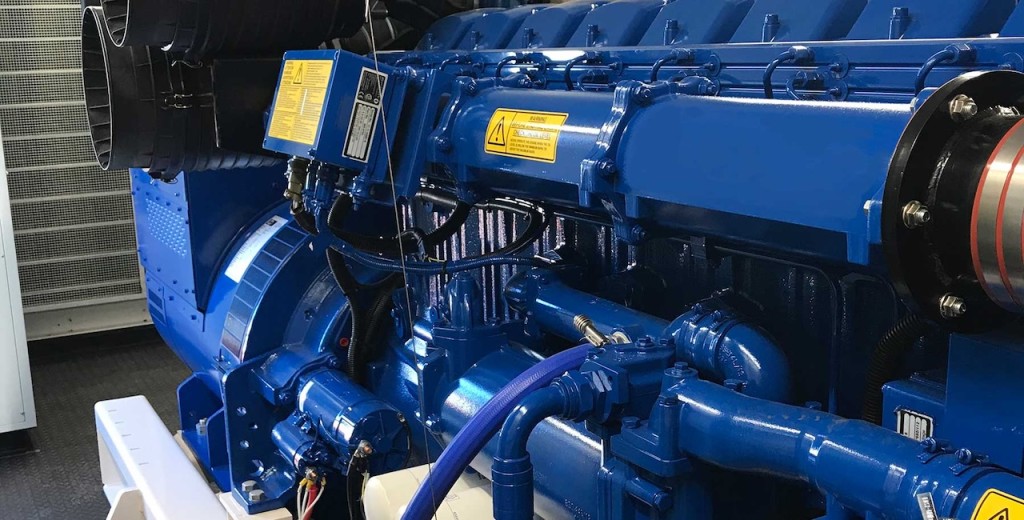

2. Internal Glazing

A generator engine relies on enough cylinder pressure to force the piston rings to tightly seal in the bore (the diameter of each cylinder) against the film of oil on the bores surface. Internal glazing occurs when hot combustion gases blow past poorly-sealed piston rings, causing lubricating oil on the cylinder walls to do what’s termed a ‘flash burn’. This produces an enamel-like glaze that removes the intricate pattern designed to hold oil and return it to the crankcase through the scraper ring.

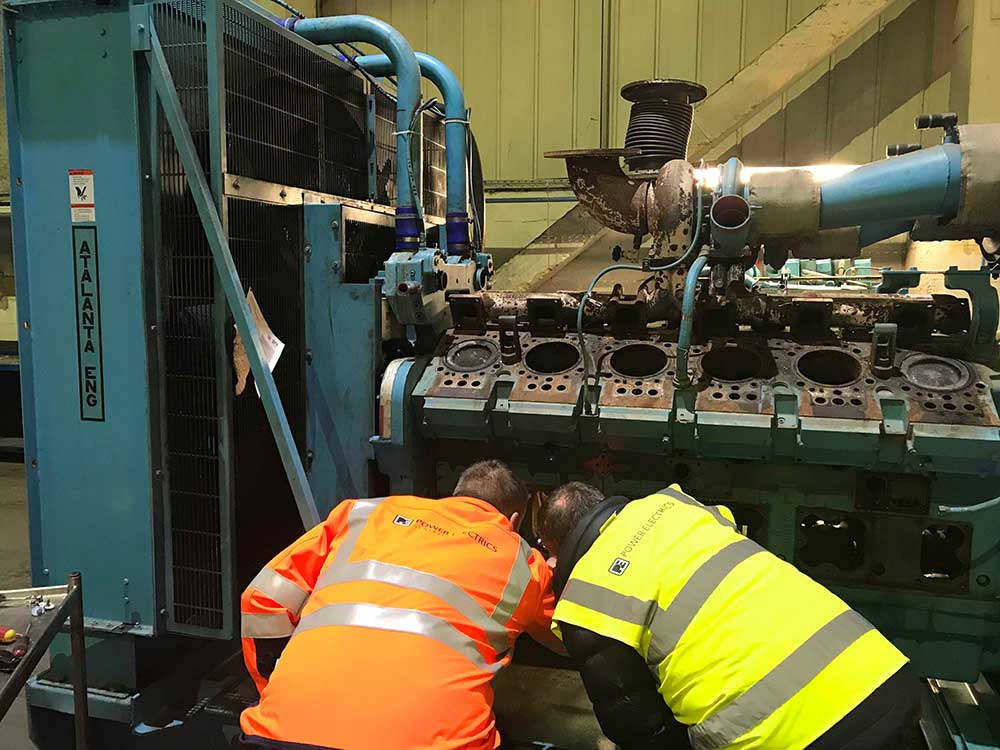

This detrimental cycle causes the engine to become irreversibly damaged and may cause it not to start and/or no longer be able to reach full power when required. After glazing or carbon build-up has occurred, the damage can only be fixed by; stripping down the engine and re-boring the cylinder bores, machining new honing marks and stripping, cleaning and de-coking combustion chambers, fuel injector nozzles and values. Consequently, this often leads to higher oil consumption and therefore a greater amount of carbonised oil or oil residue is produced. Carbonised oil is engine lubrication oil which has become contaminated with carbon deposit, this happens naturally when the engine is combusting fuel, but is excessively created when the piston rings are gummed up and cylinder bores glazed.

3. Produces White Smoke

Running a generator on low load can lead to white smoke that’s produced from the exhaust with high hydrocarbon emissions due to a lower temperature (as the fuel can only partially burn at this temperature). White smoke occurs when diesel fuel isn’t burning correctly due to a lack of heat in the combustion chamber, it also contains minor toxins that can be harmful or when water has leaked into the air charge cooler. The latter is typically caused by a blown cylinder head gasket and/or cracked cylinder head. The percentage of un-burnt fuel left in the oil therefore increases because the piston rings, piston and the cylinder can’t dilate enough to ensure a good seal, this in turn causes oil to rise which in then expelled through the exhaust values.

Other problems that can arise when a generator set is used at a load less than 30% of the maximum power value are:

- Excessive wear of the turbocharger

- Oil leaks in the body of the turbocharger

- Pressure in the gearbox and crankcase increases

- Hardening of the surfaces of the cylinder liners

- Lower efficiency of the exhaust gas treatment system (ATS) which may activate the forced regeneration cycle of the DPF.

If you have any questions about the maintenance of your generator click the button below: