The way electricity demand is managed is changing. Battery Energy Storage is increasingly being used to balance variable loads, with RenewableUK reporting a 509% increase in UK operational battery storage capacity between 2020 and 2025. While this growth is often discussed at grid scale, the same approach is proving highly effective on major civils sites, where short-term peaks and fluctuating demand are common.

What Peak-Shaving Means in Practice

Peak-shaving is the process of removing short-duration spikes from the load seen by the generator or grid supply.

Without a battery, a generator must be sized to meet the highest peak demand, even though it will spend most of the day running at very low load. This is particularly problematic for Stage V generators, which do not perform well when operating at low percentages of their rated capacity. Battery Energy Storage changes this dynamic in a way that mechanical generation alone cannot. Unlike diesel generators, batteries are not constrained by minimum loading requirements and can respond instantly to changes in demand. This allows short-duration peaks to be absorbed electrically, while the generator is sized and operated to suit the site’s average load rather than its maximum possible demand.

Why Peak Demand is a Challenge on Major Civils Sites

On major civils and infrastructure sites, electrical demand is rarely constant. Instead, loads rise and fall throughout the day, often creating short but significant spikes that far exceed the site’s average demand.

A common example of this is a site cabin complex. While the base load for heating, IT and lighting may sit at around 20–30 kW, demand increases sharply at specific times of day. When site teams arrive in the morning, kettles, microwaves and other welfare equipment are switched on simultaneously, creating a brief surge in demand that can reach 50–70 kW before dropping back down again.

These spikes may only last for 15–20 minutes, but without intervention, the entire power system must be sized to cope with them.

In a recent BES deployment on a civil construction site, pairing a 60 kVA generator with a 45 kVA BES unit cut generator runtime by almost 70% while managing variable loads.

By introducing a Battery Energy Storage (BES) system, the generator can be sized to suit the site’s average load rather than its peak demand. A defined output set point is applied to the generator, allowing it to operate within a stable and efficient range. When site demand rises above that set point, the battery discharges instantly to supply the additional power required, ensuring the site remains fully supported without increasing the generator load.

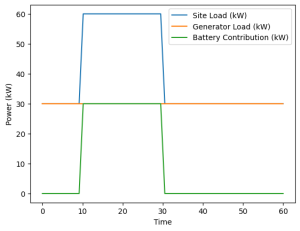

From the generator’s perspective, the load appears flat and stable. From the site’s perspective, full power is still available when required. In graphical terms, as shown in the diagram below – instead of seeing a load curve that rises sharply to 60 kW, the generator load rises to 30 kW and remains flat, while the battery supplies the difference. The graph illustrates how a BES system reshapes site demand by removing short-duration peaks from the generator load.

Diagram: Without a battery, the generator would need to support the full 60 kW peak. With BES, the generator remains at 30 kW while the battery supplies the additional demand during peak periods.

Supporting Generators and Improving Stage V Operation

BES systems work particularly well with Stage V generators because they allow the generator to operate in a more controlled way.

Rather than cycling between high and very low loads throughout the day, the generator can operate in a far more controlled way. With battery support in place, it can run consistently at around 60–70% load, or shut down completely once the battery is sufficiently charged, reducing unnecessary runtime while maintaining full availability when power is needed. This avoids the issues associated with low-load running and keeps the generator operating at more suitable temperatures.

The battery does not replace the generator; instead, it acts as an electrical energy store, allowing the generator to run less often and under better conditions.

How Load-Levelling Differs from Peak-Shaving

Load-levelling is closely related to peak-shaving but is more commonly associated with capacity agreements and grid-connected sites. According to UK Parliament analysis, electricity storage can be deployed to reduce peak demand on constrained networks, allowing users to operate within existing limits while avoiding immediate reinforcement. For civils projects operating on temporary or restricted grid connections, this approach enables progress without waiting for costly or time-consuming network upgrades.

Where a site has an agreed maximum import from the grid, load-levelling ensures that demand never exceeds this limit. A BES system can be configured so that:

- The grid supplies power up to a defined level

- The battery recharges during periods of low demand

- As soon as demand rises above the agreed limit, the battery discharges

This allows the site to operate normally without breaching capacity agreements or overloading upstream cabling. In our work with Kennington Tube Station, hybrid systems used smart controls to keep emissions and noise low while handling fluctuating loads.

Why Power Demand Challenges are More Common on Civils Projects

On a national grid, short-term increases in demand are insignificant. With many gigawatts of generation available, a sudden increase of a few kilowatts makes little difference.

On a temporary or limited power supply, however, the same increase in demand becomes far more critical. Civils sites often operate from temporary grid connections, restricted supplies or generator-based systems, where even short-term spikes can place significant pressure on the available infrastructure and dictate how the entire power system must be designed and managed.

In these situations, peak-shaving and load-levelling allow sites to pay for and operate from smaller supplies, rather than having to size everything for brief, infrequent peaks.

Responding to Rapid Changes in Demand

Site loads can change very quickly. In some projects, loads vary by tens of kilowatts within seconds as heating elements or process equipment are switched on and off.

Batteries can respond almost instantaneously to these changes. By adjusting frequency slightly above or below nominal levels, the inverter determines whether the battery is absorbing energy or supplying it, without affecting site operations.

This allows the system to maintain a stable load profile even when demand fluctuates rapidly.

Monitoring Performance Once the System is Live

Once installed, BES systems provide extensive performance data. Telemetry allows engineers to monitor:

- Load levels

- Charging and discharging behaviour

- Generator performance

- Voltage and current at inputs and outputs

This data can be used to understand how the site is operating in reality, rather than relying solely on predicted loads. In some cases, it reveals that sites are using far less energy than originally expected, allowing systems to be adjusted accordingly.

The data also belongs to the customer, helping them understand where energy is being consumed and how their site operates day to day.

Installing BES on a Live Civils Site

Most BES systems are installed early in a project’s lifecycle, although retrofits are possible. Installation begins with understanding what the site is powering — from cabins and welfare to processes, silos, concrete production or EV charging.

EV charging is an increasing contributor to morning peak demand, with some sites seeing significant additional load during arrival times.

Our engineers work with site teams to assess loads, monitor real usage, and adjust systems as new equipment comes online or site conditions change.

The Role of Engineering Expertise

Deploying BES on civils projects requires a clear understanding of how loads behave. Batteries can handle high-impact loads very effectively, but they rely on stored energy rather than a fuel tank that can be instantly refilled.

Knowing how and when energy is consumed, how the battery is recharged, and how the system will behave over a full operating cycle is critical. Site visits and real-world observation are often necessary, as key details are not always obvious from specifications alone.

Making Peak-Shaving and Load-Levelling Work on Site

Peak-shaving and load-levelling do not create energy, but they allow energy to be used more effectively. As National Grid notes, battery storage technologies are essential to the transition away from fossil fuels. Ensuring that major civils projects are compliant with meeting emissions standards. In the context of major civils work, storage already plays a practical role — not by replacing generation, but by enabling smarter, more flexible power systems that can adapt to changing loads and constrained supplies.

By combining BES with generators or limited grid supplies, major civils sites can:

- Manage short-term spikes in demand

- Keep generators operating more efficiently

- Remain within capacity limits

- Adapt as site loads change over time

When correctly designed and managed, BES systems provide a practical way to support complex, variable loads on major civils projects.