In this blog we will explore synchronising generators, how it is done, what are the benefits, and what can happen if it is done incorrectly. Some of the terminology used is specific to the generator industry, so if you are new to generators before reading this blog, we recommend having a look at our Generator Talk And How To Crack It blog.

What is synchronisation?

Synchronising generators is the process of matching two or more generators’ parameters so that the load needed to be powered can be shared. The parameters that need to be matched are the Number of Phases, Phase Rotation, Phase Angle, Frequency, and Voltage. These parameters can be synchronised automatically or manually.

Synchronising Principles

- Number of Phases: These must be equal in each system – Unmatched systems cannot be synchronised

- Direction of phase Rotation: Generator sets must be connected so that all phases rotate in the same direction

- Phase angle: The phase angle between the voltages must be very close prior to paralleling, usually within 10 degrees.

- Frequency: The frequencies of the systems being parallel must be within a small percentage of one another, typically less than 5%.

- Voltage: The voltages of the systems being synchronised must be within a small percentage of one another, typically less than 5%.

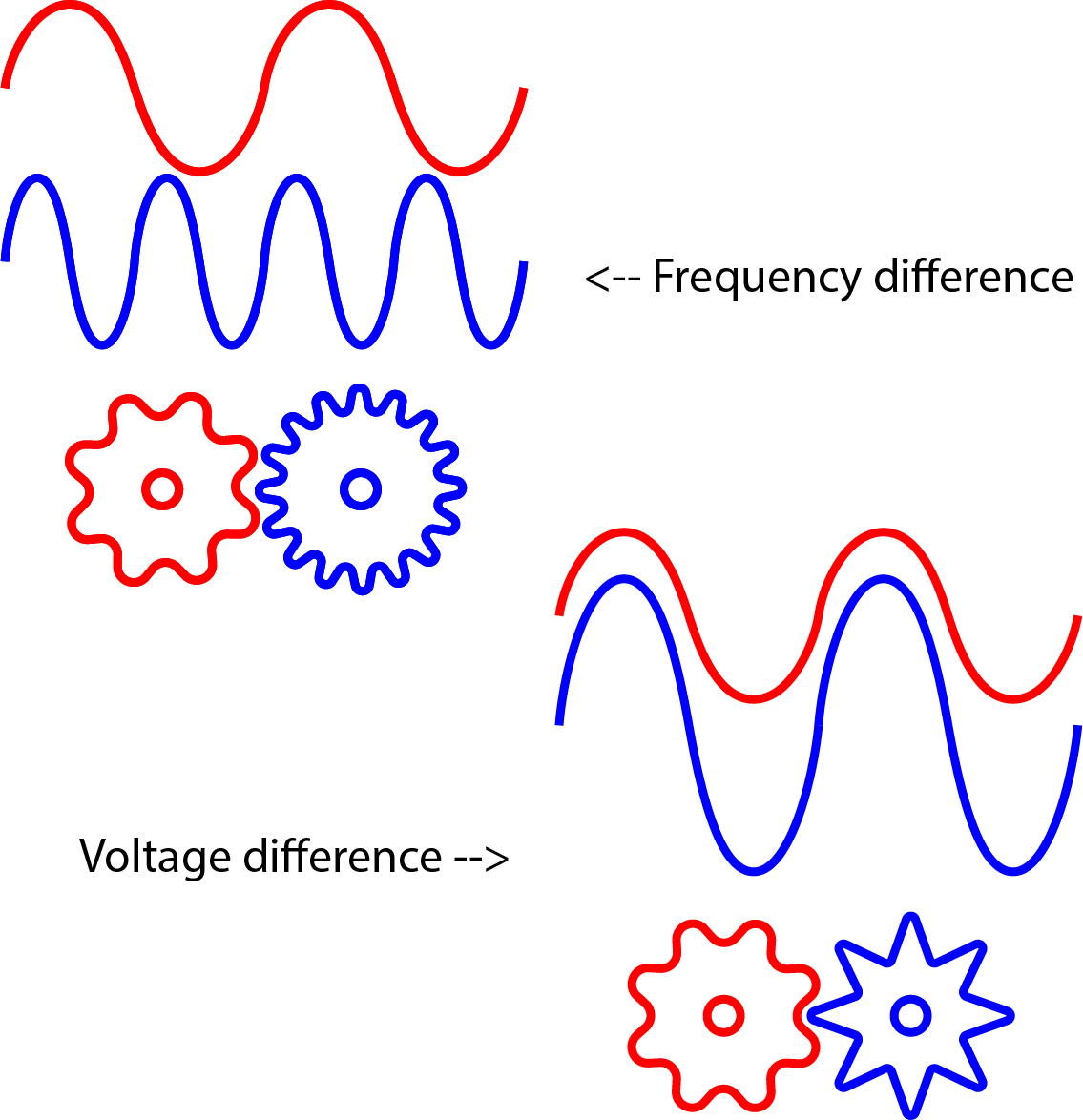

A good way of thinking about the principles is if you imagine the generators as cogs.

For example, the frequency of systems:

If Generator 1 has a frequency of 50 hertz and Generator 2 has a frequency of 60 hertz, then it would be as if two cogs were trying the mesh together, but one cog had more teeth than the other.

The cogs would then not fit together as shown in the top part of the image.

Another example is the Voltage amplitudes of the systems:

If the Voltage is different, it would result in the cogs having different sized teeth and thus would not mesh together, as shown in the bottom part of the image.

What are the benefits of synchronising generators?

Now that we have covered the concept behind synchronising, it leads us to the question, what are the benefits?

The key reasons are Reliability, Continuity, Load, Efficiency and Capacity.

Reliability

This is fairly self-explanatory, but still needs mentioning. If a generator is powering something critical and were to fail, then in a set up with multiple synchronised generators, the other units would keep the system powered.

Continuity

Similar to reliability, if a generator were to need maintenance the other units can keep running whilst it is being serviced.

Load

Load required to be taken on throughout the day can vary, so by having multiple generators sharing the load, they can turn on or off when needed. This can help reduce costs and emissions.

Efficiency

Generators run most efficiently when at their optimum load rating, so by sharing the load generators can be run more often at this optimum load.

Capacity

The bigger the load required the more power that is needed, with a multiple-generator setup you can add more generators to take on the load.

How to synchronise?

In the majority of cases for generator synchronisation, the synchronisation process is automated via an automatic synchroniser or control panel with manual control capabilities, allowing for manual takeover if needed.

For a system to automatically synchronise it must be able to:

- Monitor the voltage and frequencies of both systems to be paralleled.

- Bias the alternator voltage and engine speed.

- Issue a breaker close command.

The Effects of Incorrect Synchronisation

Incorrect Synchronisation can be very damaging to generators and could cause a number of problems. From reduced efficiency and reactive currents to power surges and mechanical or electrical stresses on the system (known as “Crash Parallel”), and ultimately could disable any and all systems in circuit.

Thank you for reading our blog on Synchronisation, if you have any questions about the topics discussed in this blog, or to find out how Power Electrics can help you with temporary power for your next project, please reach out using the link below and we will be happy to help.