When a school in the North West of England was forced to close part of its main building due to concerns over Reinforced Autoclaved Aerated Concrete (RAAC), temporary classrooms were brought in to keep education going. Working with Greener Power Solutions, Power Electrics provided a reliable and low-emission power solution for the new units.

The priority was to deliver a system that could be deployed quickly, run efficiently and ensure resilience in a residential area.

The Challenge

The school needed continuous power for modular classrooms placed on the school grounds. As the site was no longer connected to the grid, a complete off-grid solution was required. Noise levels also had to be kept low to avoid disruption to lessons and to the surrounding neighbourhood.

High load peaks during the school day, combined with low demand overnight, called for a system that could manage fluctuating usage without compromising on reliability or efficiency. The setup also had to ensure 24/7 supply assurance, with strong backup capabilities and low emissions across the entire lifecycle.

The Solution:

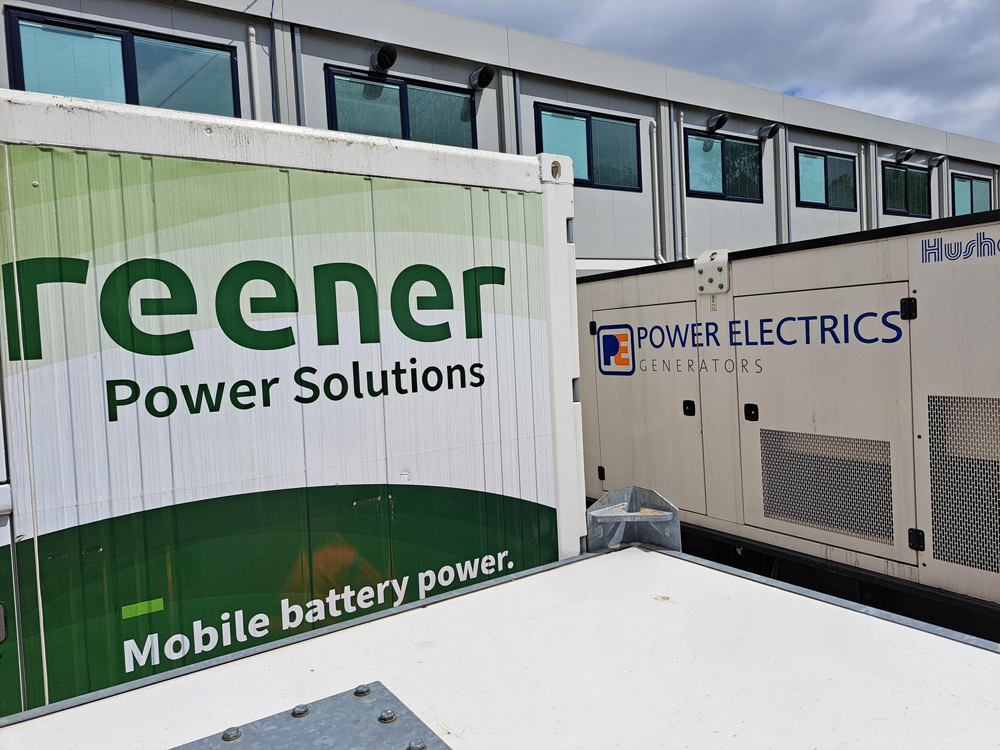

The solution needed to utilise the best of both worlds: the benefits of a traditional diesel generator combined with the sustainability of a BESS unit. Power Electrics, in partnership with Greener Power Solutions designed and delivered a hybrid microgrid solution consisting of:

– A 318 kVA / 420 kWh Battery Energy Storage System (BESS)

– A 275 kVA generator in island mode

– A 275 kVA fixed export generator connected to the load side of the battery

– 2 x 3000 litre tanks

– Bespoke Distribution Board

The battery is the main power asset and forms the microgrid at 400 volts/50 Hz, providing energy to the load. When the primary generator is started by the Greener EMS, the frequency and voltage across the system synchronise, allowing the battery to perform peak shaving while recharging. This setup delivered clean, silent power throughout standard operations, with the generators only activating when required–either to recharge the battery or during peak demand.

During high-demand periods, the fixed generator steps in to assist or take over, adding resilience and ensuring uninterrupted power. A bespoke distribution board tailored to the site’s specific load requirements further enhanced system efficiency.

This configuration also includes smart redundancy: if one generator fails or if site load increases beyond what the primary generator can handle alone, the system automatically starts the second generator to export energy to the load or battery. This seamless switchover capability guarantees continuous performance even during unexpected demand spikes.

The Results

The system provided reliable power to the temporary classrooms throughout the school year, with no unplanned outages. By combining a BESS Unit with two 275 kVA generators, we reduced generator runtime by more than 6,350 hours compared to a standard single-generator setup. This led to a saving of almost 60,000 litres of fuel and prevented over 190 tonnes of CO2 and 930 kilograms of NOx from being emitted.

The battery managed low loads and overnight demand, which helped keep the site quiet during sensitive hours and further reduced emissions. This was especially important in a residential setting, where noise reduction and air quality were key concerns.

This project shows what’s possible when smart technology is paired with practical design. It delivered dependable power, lowered environmental impact, and kept disruption to a minimum. It is a clear example of how we are helping organisations move toward cleaner, quieter, and more easily emission-free power–without compromising on performance.