Some organisations face the issue of having an electrical demand that’s higher than the local grid’s supply capacity. A large drinks manufacturer based in Somerset faced this very challenge and came to Power Electrics for help.

The Challenge

The site was almost at Distribution Network Operator (DNO) supply capacity, which risked the DNO turning it off. Power Electrics were brought in to come up with a temporary solution, with a peak lopping application deemed the best solution. Power Electrics recognised that to provide a temporary generator integrated into the site system; it had to comply with both G99 and G100 engineer recommendations.

G99 covers the requirements for the connection of generation equipment in parallel with public distribution networks, and G100 covers the requirements for the connection of customer Export Limiting Schemes (ELS) that operates in parallel with the distribution systems of licensed DNOs.

The Solution

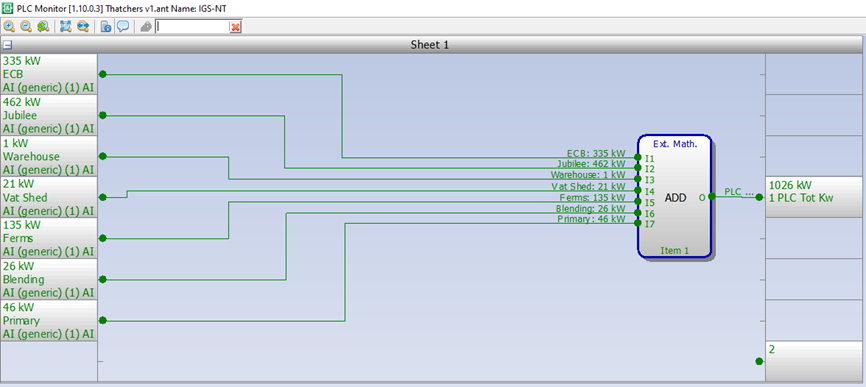

To solve the challenge, Power Electrics provided a temporary 500kVA generator configured for Peak Lopping operation. Peak Lopping is a mode of power control whereby the generator supplies part of the site’s load when energy demands hit a pre-determined threshold. Utilising a ComAp InteliFieldbus Gateway to read the kW information over Ethernet (Modbus TCP) this translated the reading into Comap CAN BUS language. Each of the site exiting power meters were used as reference points, and when combined using a mathematical summation function within the onboard PLC to sum the site demands it created a single value for total site load.

This then allowed for use of the internal Peak Lopping functions. The genset monitored the total site load and the generator started when the Peak Start valve is exceeded for more than the Peak Start/Stop delay. The generator then synchronised with the mains, to supply c.400kW of load into the local system. Once operating the generator will continue to monitor the total site load and will stop the generator if the load drops below the Peak Stop valve for more than the Peak Start/Stop delay.

“Power Electrics managed the entire process, which included the proof of concept prior to delivery, the organisation and management of the DNO for witness testing and the G99/G100 Test Engineer – a total managed solution.”

Alex Hill, Business Development Manager

For a 4-month period, the temporary generator solution supported the site, mitigating any risk of isolation by the DNO. Hired-in Generators configured for Peak Lopping can be a cost-effective upgrade to an electrical supply solution when other options are not viable i.e. 24/7 running of a generator and its associated fuel costs, or when DNO upgrades are not economical and have long lead-times.

Thanks to the expertise of Power Electrics’ engineers, the drinks manufacturer was able to continue its operations without risk of the facility’s power being isolated, along with the temporary solution being within budget and no increased funding required.

“Whilst we provide these solutions for numerous customers, it is typically for fixed generation assets, as part of new developments, it was an interesting and rewarding project to technically lead and be part of; with the integration into a unique site network, plus the client’s timescales for solutions.”

Dave Potter, Commissioning Engineer